Title and Credits

OASIS VINEYARD TRIAL RESULTS

6th Harvest (8th leaf), 2024

by Josiah Hunt, Charlie McIntosh, Doug Beck, and Raymond Baltar

Introduction

The Oasis Vineyard field trial with biochar and compost began in 2016 as a California Department of Water Resources funded grant project led by Sonoma Ecology Center (grant admin), UC Riverside (principal investigator), Monterey Pacific Inc (vineyard manager), and Pacific Biochar (biochar supplier) to study the impact of biochar and compost treatments applied pre-plant in newly established vineyards under a standard irrigation and fertilization regime. After 8 years collecting data, covering 6 harvest seasons, significant emerging trends are highlighted with discussion below.

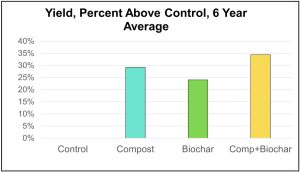

- Harvest Yields were increased by an average of more than 30% where biochar and compost were applied together.

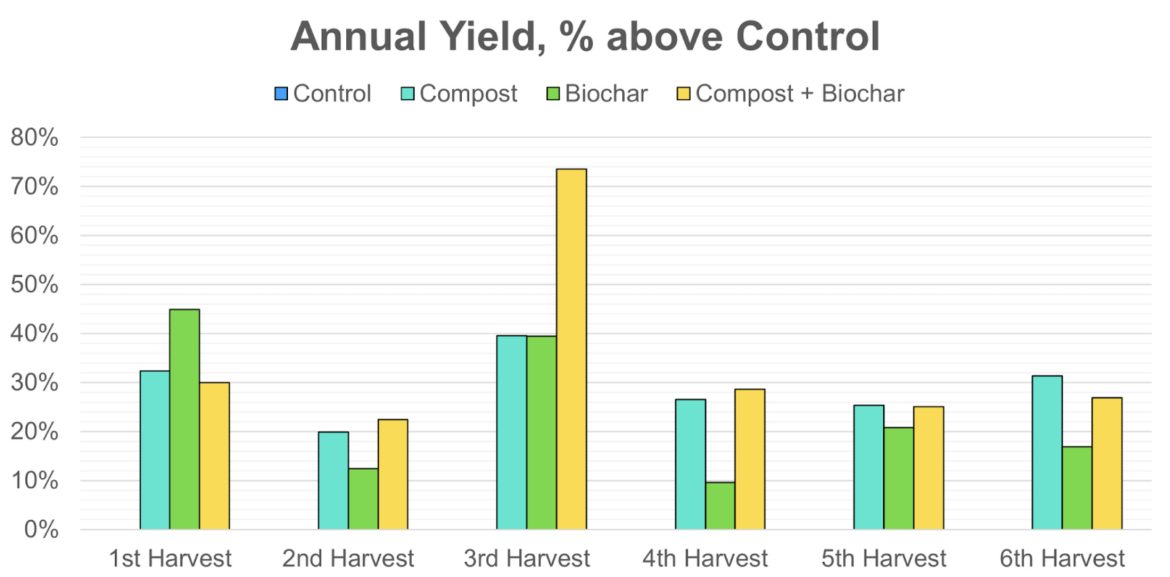

- Harvest Yields by Season. In the lowest-yielding harvest years, all treatments showed exceptionally high percentage of yield improvement, with compost + biochar greater than 70% in the third harvest.

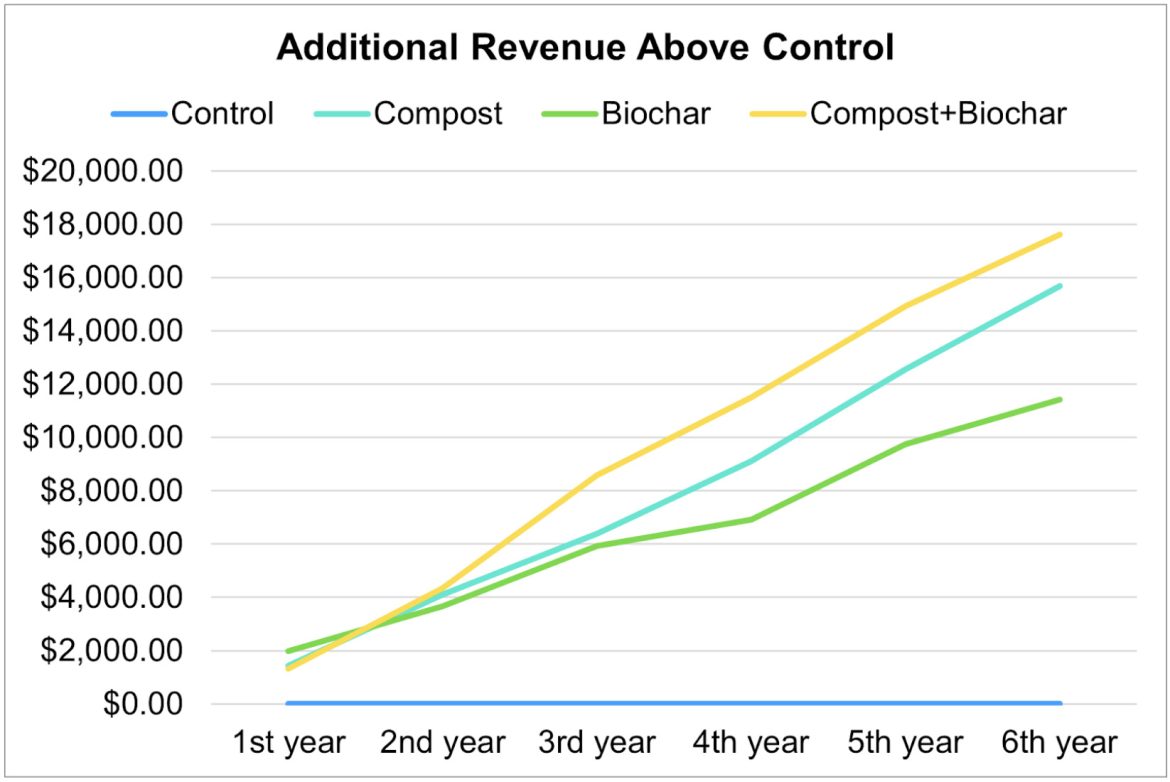

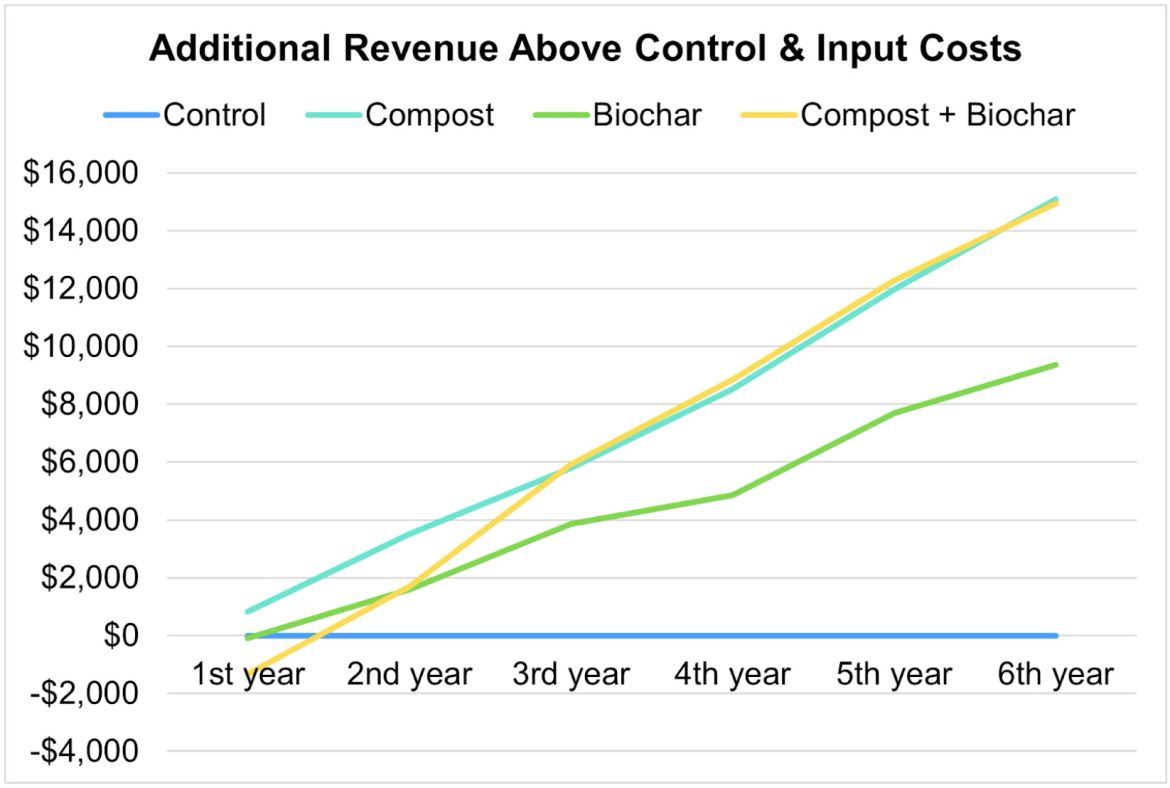

- Economic Impact. All treatments had a positive return on investment by second harvest, and by sixth harvest provided $11,432, $15,689 and $17,607 additional revenue per acre where biochar, compost, and biochar+compost were applied, respectively.

- Grape Quality was not significantly affected

Overview

The Oasis Vineyard Trial is located on an 8 acre site in Monterey County. Soil type is primarily Oceano Sand at 0.7% organic matter content; other areas could be described as Garey Sandy Loam with the same low level of organic matter. In 2017, Pinot Noir clone 456 on 1103P rootstock were planted at 9 x 5 spacing and grown with the high-wire box pruned style trellis system. Prior to planting, soil amendments were applied in a ripped delve down the vine row using GPS, then mixed with a winged plow to a depth of 30 inches in a ‘bowl’ approximately 2 feet wide by 2.5 feet deep. Compost was provided by Keith Day and biochar was provided by Pacific Biochar. The compost was derived from greenwaste and ag residue and produced in Monterey County, CA. The biochar was derived from high fire hazard forest residue and produced in Shasta County, CA. All treatments received the same irrigation and fertilization regime

- The biochar as applied (10 ton/acre, 38% moisture content, 75% organic matter content) was equivalent to a 0.42% SOM increase in the planting row.

- The compost as applied (15 ton/acre, 49% moisture content, 43% organic matter content) was equivalent to a 0.30% SOM increase in the planting row.

- The compost + biochar as applied (15 ton/acre compost + 10 ton/acre biochar) was equivalent to 0.72% SOM increase in the planting row.

Treatments

(All treatments received the same irrigation and fertilizer regime)

Control – 0 tons/acre compost, 0 tons/acre biochar

Compost 15 – 15 tons/acre compost (wet weight)

Biochar 10 – 10 tons/acre biochar (wet weight)

Compost + Biochar – 15 tons/acre compost, 10 tons/acre biochar (wet weight)

Harvest Yields

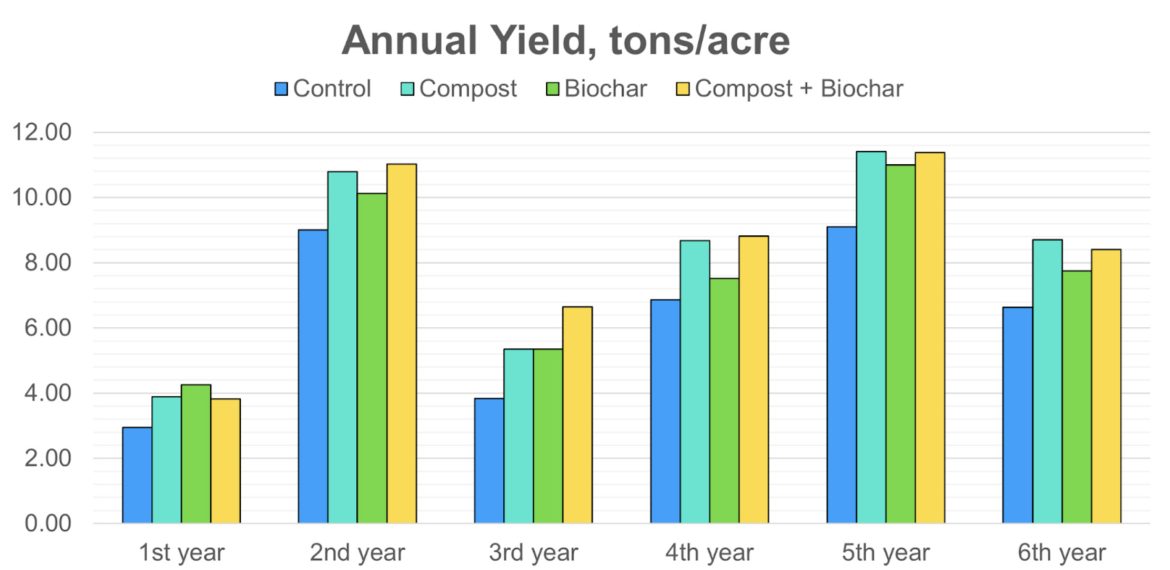

Highest total combined yields for all five seasons were seen in the compost+biochar plots (50.1 tons/acre) compared to both the biochar alone plots (46.0 t/ac), the compost alone plots (48.8 t/ac), or the control plots (38.4 t/ac). The averaged increase in yield was 34%, 24%, and 29% for the compost+biochar, biochar, and compost treatments respectively.

Highest total combined yields for all five seasons were seen in the compost+biochar plots (50.1 tons/acre) compared to both the biochar alone plots (46.0 t/ac), the compost alone plots (48.8 t/ac), or the control plots (38.4 t/ac). The averaged increase in yield was 34%, 24%, and 29% for the compost+biochar, biochar, and compost treatments respectively.

Economic Impact

For an economic assessment, we used the price of grapes as of October 2024 (about $1,500 per ton); the price of compost and biochar as delivered in 2016, $40/ton and $206/ton respectively (wet weight). The inputs of water and fertilizer had the same cost across all treatment types. It is important to note that the revenue increase observed is highly dependent on the price per ton of grapes, which can vary widely.

When measuring grape revenue, the treatments provided substantial revenue increases beyond that of the control plots during the first six harvest seasons: $15,689 additional revenue for the compost treatment, $11,432 for the biochar-alone treatment, and $17,607 from the combined compost+biochar treatment.

When subtracting the costs of the soil amendments from the additional revenue they provided, a rough calculation of profit can be assessed: $15,089 profit resulting from the addition of compost; $9,372 profit resulting from the addition of biochar-alone; and $14,947 profit resulting from the combined compost-biochar treatment.

From this perspective, all treatment types produced increased value, with all of them providing a positive return on investment by second harvest. While the compost-biochar combination was the most expensive treatment in this trial, it also shows the greatest yield increase.

The woody biomass biochar used in this trial was produced at a relatively high temperature (>600C), and the vast majority of it (>80%) is projected to persist in the soil where applied for at least 100 years (Greenhouse Gas Inventory Model for Biochar Additions to Soil, Woolf et al, 2021), where it can continue to provide benefits over the lifetime of the vineyard and beyond. If we assume that yield increases were to continue over the next 4 years, but only at half the rate observed so far, then when looking at the biochar treatment alone, an additional $3,810 per acre would be added to the cash returns on the initial biochar investment. This would total $15,242 in gains per acre in a 10 yr period, greater than 7x return on the biochar investment. And if we stretch this same economic projection to a total of 20 harvests, such as might be a common time before replanting, gains would total $24,769 per acre, greater than 12x return on the biochar investment.

Grape Quality

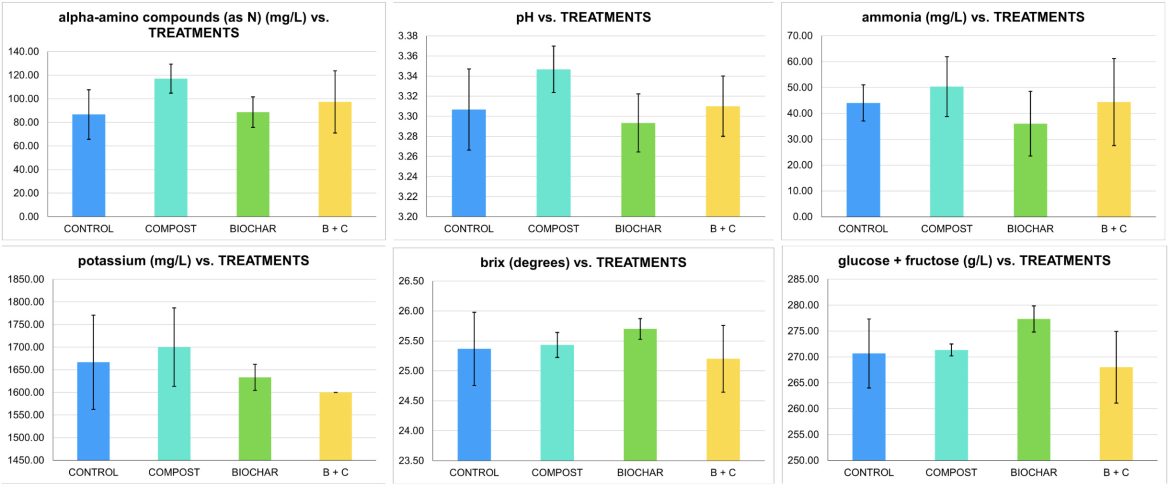

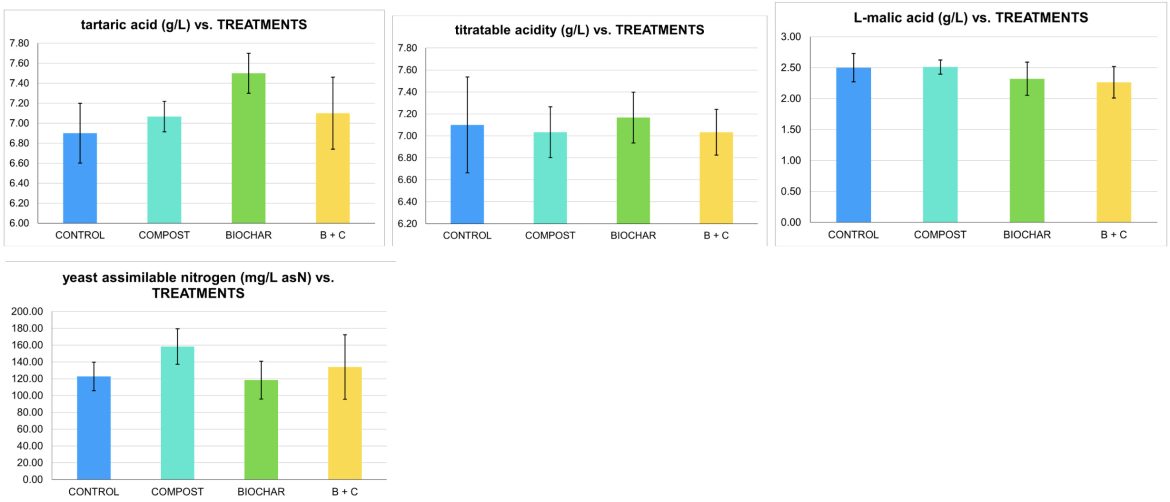

We also investigated soil treatment impacts on fruit quality. In summary, although there were significant increases in yield quantity, there were not significant observed differences in grape quality.

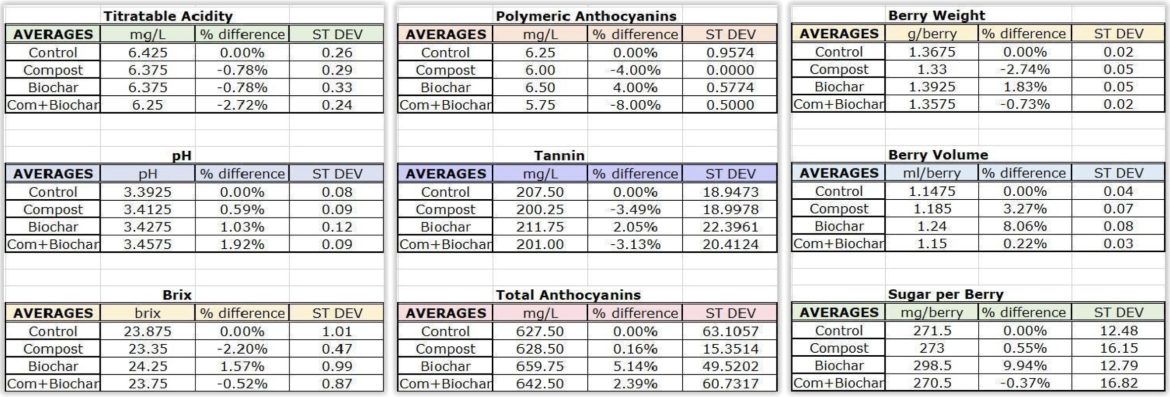

Second Harvest, Grape Quality Analysis

In the second harvest, fourth leaf, we analyzed 2x 300-berry samples from each subplot. Samples were tested at ETS Labs for the Grape Phenolic Panel and Grape Maturity Panel, Dyostem. Sugar accumulation (brix) was highest in the biochar only blocks, but not significantly. Acidity was also increased in the treatment areas receiving biochar, but again not significantly. Adding biochar to the soil appeared to increase berry volume, weight, and sugar per berry levels as compared to the control plots. Similarly, color (anthocyanins) and tannins, both positive quality characteristics, were increased in the biochar only treatment areas, though not always significantly. These positive grape quality enhancements from biochar treatment are intriguing, and further highlight the absence of any observed negative impacts from the biochar applications in this field trial.

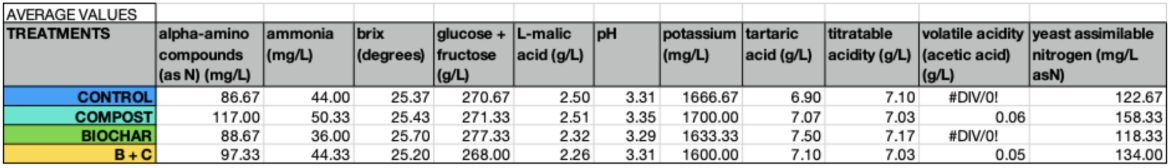

Fifth Harvest, Grape Quality Analysis

In the fifth harvest, 7th leaf, we sent 300-berry samples from each treatment to ETS Labs for a Juice Panel analysis. The differences between treatments were marginal and generally less than standard deviation. This indicates that, despite significant increases in yield, there was no significant change observed in grape quality.

“I was hoping there might be lower K in the juice panel and perhaps some significant difference in yeast assimilated nitrogen and alpha amino N, but that was not the case. From a wine maker’s perspective, I don’t see much of a positive or negative impact other than brix.”

– Steve McIntyre, Monterey Pacific (regarding fifth harvest juice panel data)

Conclusion

Measured over a period of 6 harvests, all treatments of biochar and compost resulted in significant yield increases without significant changes observed in quality. The yield increases from all treatments were greatest in the lowest yielding years, suggesting that the treatments helped mitigate yield loss due to adverse conditions. All treatments received the same irrigation and fertilization regime, demonstrating increased water and fertilizer use efficiency. All treatments were profitable by second harvest, dramatically more so in sixth harvest, and with an intriguing potential for biochar applications to provide continued returns for the lifetime of the vineyard and longer.

Download full PDF of the 6th harvest report

You can download a full PDF version of the Oasis Vineyard Field Trial with Biochar and Compost, 6th Harvest : Oasis Vineyard Field Trial with Biochar and Compost_ 6th harvest

Previous reports from the Oasis Vineyard field trial with biochar and compost

5th harvest report can be found here – 5th harvest report

3rd harvest report (and final science report for CA DWR grant) can be found here – 3rd harvest report

2nd harvest report (and first published science report for CA DWR grant) can be found here – 2nd harvest report